Overcoming Development Challenges with HiL Testing

Developing ECUs for the automotive, aerospace and industries is challenging, requiring stringent safety standards, realistic simulations, and tight timelines. Traditional test methods - which are expensive, slow, and inflexible - can no longer keep up.

Hardware-in-the-Loop (HiL) testing offers a modern solution, combining physical hardware with simulated environments for efficient validation. By enabling realistic, repeatable testing, it reduces the need for expensive prototypes and minimizes real-world testing efforts.

Key Benefits of HiL include

The picture shows how sensors from cars and airplanes are simulated and tested in a HiL test environment in order to validate the functionality of the sensor

HiL Solutions for Performance and Precision

At b-plus we understand the increasing complexity of system validation. Our HiL solutions are designed to meet the demands of modern automotive, aerospace and industrial development. With advanced replay software at their core, our solutions enable real-time replay of high-bandwidth data streams such as radar, lidar and video. This ensures that systems are validated under real-world conditions, delivering peak performance and safety.

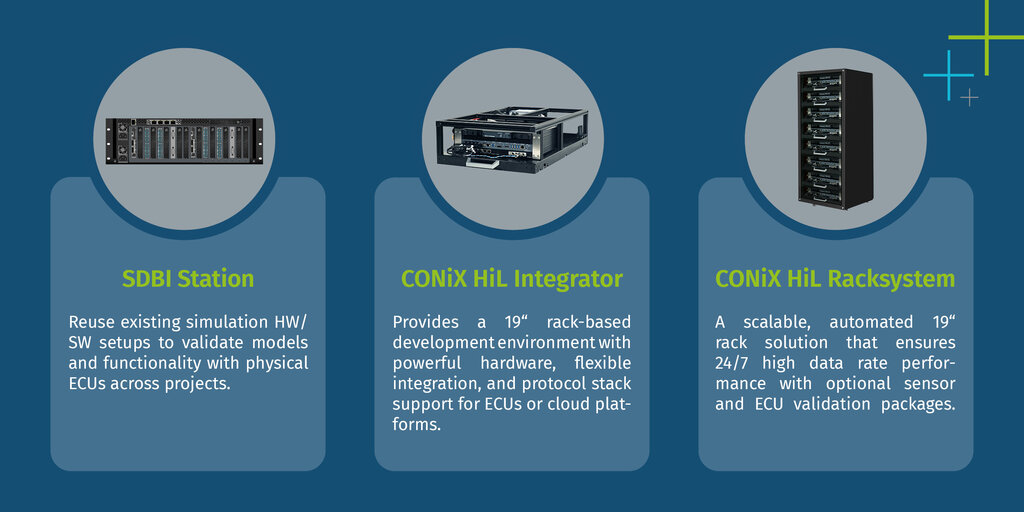

What makes our Solutions different?

The image shows our scalable HiL solutions for simulating, developing and validating ECUs and sensors.

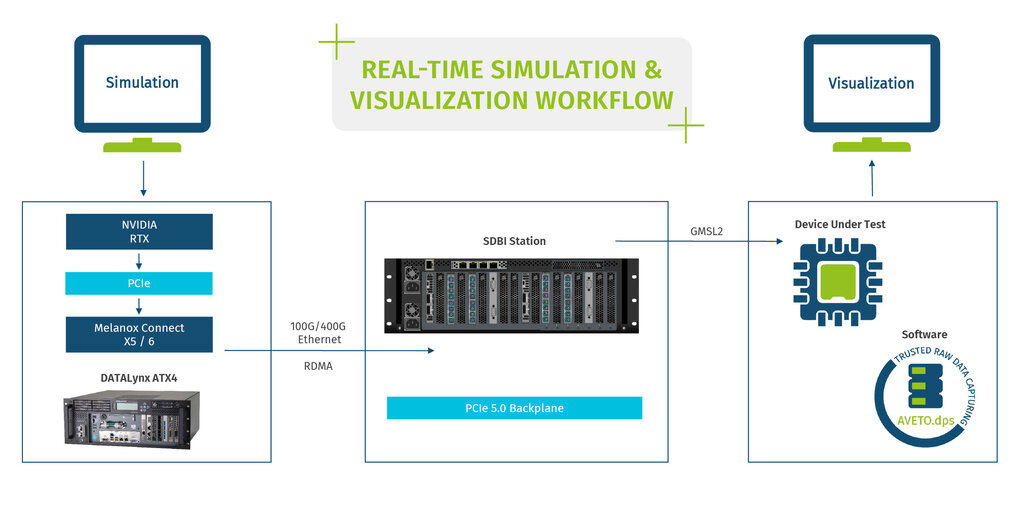

Our Simulation Data Bridge and Inject Station

The latest addition to our HiL portfolio, the SDBI Station, redefines the efficiency and accuracy of system validation. This innovative solution provides a cost-effective, high-performance platform for validating ECUs, sensors and autonomous driving systems.

With its advanced PCIe-based architecture, the SDBI Station offers unmatched speed, scalability and flexibility. Whether you're validating autonomous driving systems, sensors, or ECUs, it gives you the tools to tackle even the most challenging scenarios with confidence.

Why Choose the SDBI Station?

The image shows our SDBI station, optimized for accurate real-time data playback, simulation, and reliable 24/7 validation of vehicle systems with minimal latency.

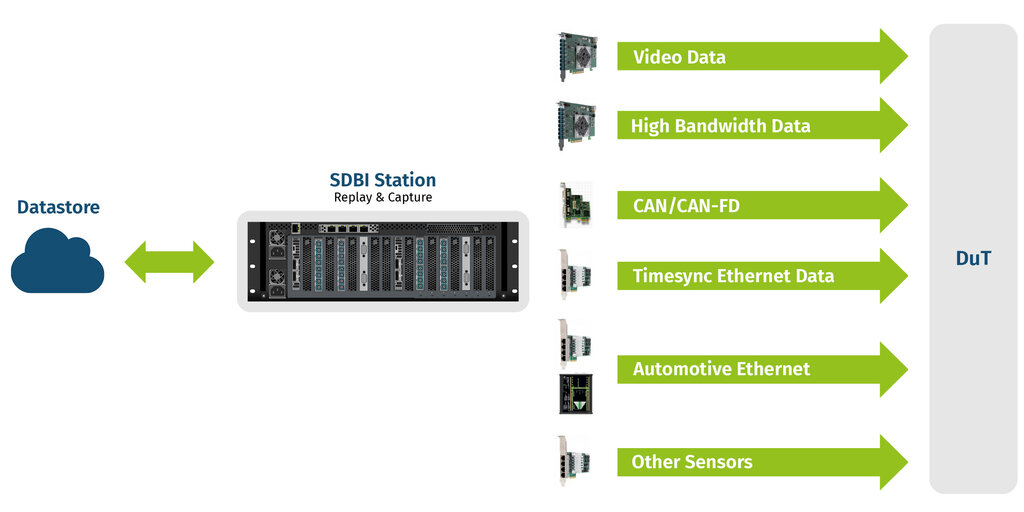

Validation of Central ECUs with HiL Simulation

The SDBI Station enables the acquisition and playback of multiple data streams, e.g. video, radar, LiDAR, CAN, Ethernet, and other sensors. It provides a high-performance, real-time validation environment for central ECUs, ensuring accurate testing of system functions, e.g. autonomous driving function under realistic conditions. By replicating real-world sensor inputs with minimal latency, it accelerates development and improves system reliability.

The image shows our SDBI station, which is used to capture and playback various types of automotive data - such as video, CAN, Ethernet, and sensor data - to validate vehicle systems.

Comprehensive Validation for Real-World Success

Our solutions simplify your development process, reduce costs, save valuable time and ensure that your systems perform reliably under real-world conditions. Discover how our HiL solutions can transform your validation processes!